Workshop 5 Resources - Soldering

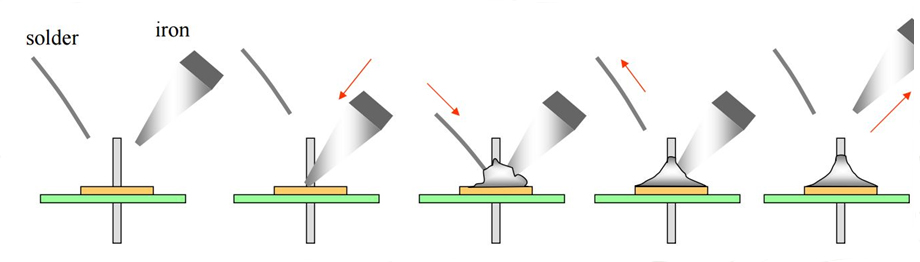

The soldering iron is not a paint brush!! We are not loading it up with solder and wiping it on the joint. What we want to do is heat up the two surfaces to be joined with the soldering iron and introduce solder to them, NOT the iron. There are a few important things to remember.

- Keep your soldering iron tip clean and tinned - clean your iron on a damp (not wet!) sponge pad or much better some brass wool and flow some solder over the surface of the tip and wipe it off so it looks shiny, do this very regularly and every time you are about to turn the soldering iron off or first thing when you turn it on

- Keep the joint still - use some helping hands clips or something to completely stabilise the work before you solder, if things move while the solder is cooling then you won't get a good joint.

- Make sure both surfaces are heated - if one is hot but the other not, then the solder might only flow around the one and leave a gap around the other, you will end up with a 'cold' solder joint which does not conduct, or may conduct at first and fail later. This is why we apply the solder to the work, not the iron, so we know it is the right temperature.

- Make sure your tip is conducting heat well - we want to add a bit of solder to the iron, a small bit, just to make sure that it is connecting to the two surfaces well and conducting heat as it should

- Choose the right tip - Generally I hate the pointed tips that come with a soldering iron and prefer a chisel shaped one, I find the heat distribution a lot better and feel I can work much more quickly and easily without getting the components to hot, though for very fine work I might go for a pointed one. The point is to use what works for you, just try the different ones available and see which you like best, you don't have to stick with the one it came with.

- Don't be afraid to start again - if its bad, really bad, use a solder sucker and take the excess solder off and start again